What is a Rosin Press and What Types of Rosin Press Are Available?

It was back in 2015 that Rosin made its entrance into the concentrate market, and in that time, it has become quite popular, but it certainly has the potential to become more widespread. During these last two years, the processing of this unique solvent-free concentrate has led to several new innovations to help with the rising demand of technology to produce the Rosin.

The extract BHO (Butane Hash Oil) was rather popular before the introduction of Rosin, but this was an extract that made use of solvents, and needed a lot of equipment. Plus, it was time consuming to harvest the resin required to make BHO. This is something that Rosin avoids, because it only needs heat and pressure. It also requires less time to process and it is possible to yield some Rosin in just a few seconds.

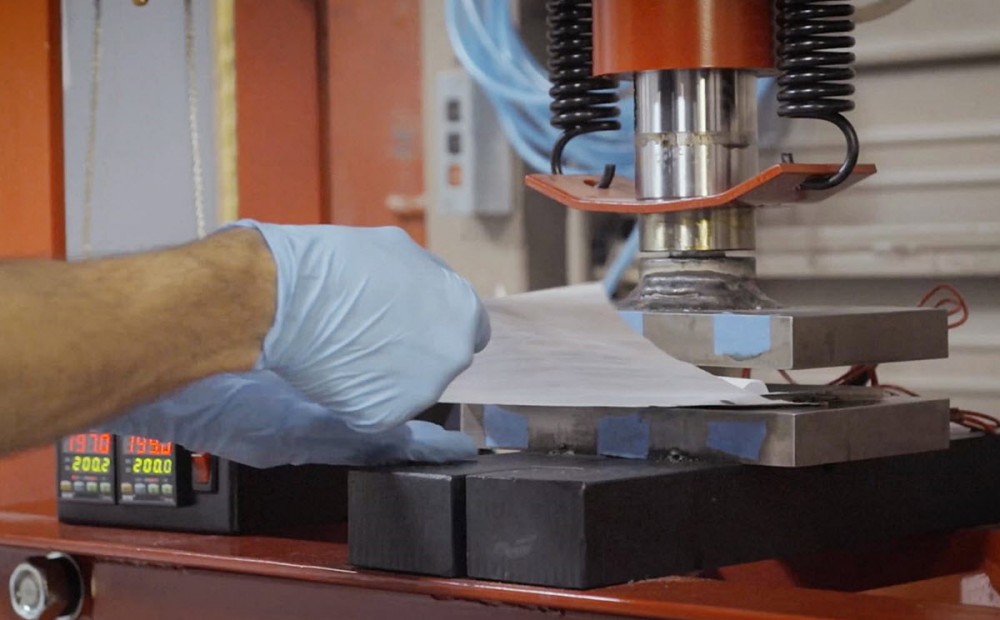

The Rosin Press is central to the Rosin production process. This is basically a machine which produces controlled amounts of heat and pressure. The technology used in the Rosin Press has improved greatly over the last few years from its simple beginnings, and as Rosin becomes more and more popular, the quality of the Rosin Press will only improve.

How does the Rosin Press Work?

As explained earlier, to make Rosin, we just need heat, pressure & time. For the process to be successful, it is important to balance the heat, pressure and time to harvest the very best quality Rosin.

In the process of extracting Rosin, it is important to control the heat to ensure that you carefully preserve the terpenes and cannabinoids that the Rosin contains. If you set the temperature too high, the terpenes and the cannabinoids will be destroyed, which leads to a poor final harvest and the Rosin will be unusable. Because of this, you should focus on producing the Rosin at low temperatures to maintain these terpenes and cannabinoids. By reducing the time exposed to very high heats, it will result in the preservation of most of the terpenes, but the only way to guarantee that you will not have any degradation is to complete the process at the lowest possible temperature.

But, when you reduce the heat, the pressure needs to be increased in its place. These high pressures can limit any degradation and keep the terpene and cannabinoid profile stable. The very best Rosin Press machines can offer enough pressure so that the process can be completed at the lowest possible temperature to guard against any degradation of the terpenes and the cannabinoids.

The First Ever Rosin Press – A Pair of Hair Straighteners…

This may sound quite surprising! But, it is a widely-held belief that the very first Rosin Press was actually a pair of hair straighteners, as straighteners could offer heat, pressure and time, just like the modern Rosin Press. Sure, the hair straighteners were not as good as the Rosin Press machines we see today, but it was quite an effective method for extracting these resins. In fact, they are still used today by people who don’t have access to a Rosin Press.

What is the Process of Making Rosin Dabs with Hair Straighteners?

To do this, simply get a pair of hair straighteners and get hold of a clamp. It is possible to get quite high rates of pressure using the clamp, but the process will be limited in success compared to a more advanced Rosin Press. Give it a go, as it may be useful for doing this process when you are wanting to extract resins on the go.

Modified Hat Press

Before the more modern Rosin Press came into the fray, the Modified Hat Press was a pretty popular method of extraction. How do these Modified Hat Press machines work? Well, a conventional Hat Press usually works by heating the top plate on its own. But, by modifying this Hat Press by heating both the top plate and the bottom plate, it is possible to be used in the production process of Rosin.

These Modified Hat Press machines made their way to market around the summer of 2015. But, the Modified Hat Press has some disadvantages, as it wasn’t able to offer the high levels of pressure for the temperature to be decreased to such an extent where the terpenes could be preserved.

Pneumatic Press

The Pneumatic Press followed quickly onwards from the Modified Hat Press. It can deliver high pressures thanks to compressed air, and the Pneumatic Press could achieve 2000psi, which is quite a high pressure. Since it is possible to control the heat with this press, as well as the pressure, the Pneumatic Press is an efficient way to extract Rosin in a matter of seconds.

These Pneumatic Press machines can be quite expensive, as they make use of a lot of technology. But, several Pneumatic Press products have entered the market, which has decreased the price slightly.

Hydraulic Rosin Press

If 2000 psi isn’t enough pressure for your needs, your next port of call should be the Hydraulic Rosin Press. It can offer pressures upwards of 20,000psi, thanks to hydraulic cylinders. This enables you to decrease the temperature quite substantially, thus preserving your terpenes and cannabinoids. The Hydraulic Press can provide a large surface area for the pressing process, so you can produce quite a lot of Rosin at once.

As you will notice, the development of the Rosin Press is still in its infancy, but developing day by day. Competition is increasing in the space, which will fuel development of bigger and better Rosin Press machines. When you are browsing for a Rosin Press, you will find the Modified Hat Press, Pneumatic Press and the Hydraulic Press all for sale. Be careful of cheap inferior products. If you want the very best Rosin Press, we would recommend building your own from the ground up. Good luck!

OTHER STORIES YOU MAY ENJOY...

WHAT IS ROSIN AND HOW DO YOU MAKE IT? CLICK HERE.